As a rule, you should go into any workspace with a proactive and preventative safety approach. This is especially true of high-risk environments like tunnels, pipelines, storage tanks, and trenches. Implementing these confined space safety tips can help you control the hazards around your site and prevent injuries and other incidents.

Confined space safety precautions

There are many different hazards workers to control in confined spaces. Some examples of these hazards include toxic gases, potential cave-ins, flammable substances, and oxygen deprivation.

Here are some confined space safety tips to implement so you can guard against these and other hazards:

- Before starting work activities, find and remove safety hazards.

- Test your communication system (radios, phones, etc.) before entering a confined space.

- Inspect respirator equipment for leaks before each use.

- Verify that ventilation system is on and functioning properly.

- Maintain updated confined space entry permits.

- Regularly test the air quality using atmospheric testing devices, gas monitors, and more.

- Perform a PPE fit check of gloves, goggles, and respirators.

- Make sure that entrances and exits are clearly marked.

- Block off confined space entrances to anyone who does not have a proper permit.

- Lock out hazardous equipment while making repairs or adjustments.

- Be sure to turn off any equipment and power tools before leaving a confined space.

- Periodically review the emergency evacuation procedures.

If you make these practices part of your standard work, you should be able to greatly reduce the likelihood of safety incidents.

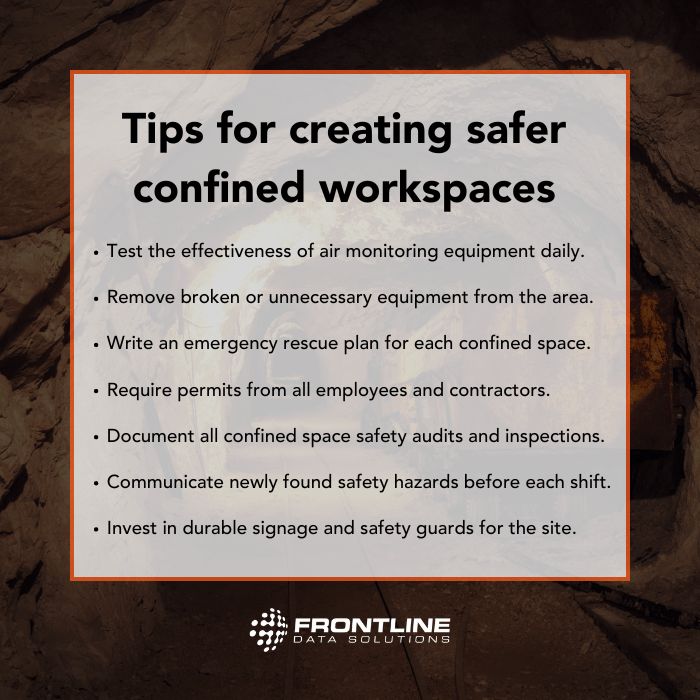

Ensure the safety of confined spaces

Confined spaces pose many health and safety risks, so regular monitoring is necessary to control them. Here are some control measures you can put in place to make these spaces safer:

- Provide confined space safety training to all workers (contractors included)

- Inspect the area multiple times per day to maintain safe conditions

- Remove broken or faulty equipment and red tag it for repair

- Develop a detailed emergency rescue plan

For compliance purposes, document all your confined space audits in case there’s an incident. That way, you have a clear account of the work conditions before the incident to help your investigation.

Document confined space audits

The best practice for documenting safety audits and inspections is to use EHS software, like Frontline ACT. Cloud-based storage of EHS documents allows you to view them from any computer. This gives you greater flexibility when managing a large facility or remote excavation projects.

To learn more about Frontline ACT for safety audits, check out the video below or schedule a demo with the sales team.