Eliminating food safety issues

Since the passing of the Food Safety Modernization Act in 1938, companies have made major strides in protecting public health and safety. However, there are still an estimated 48 million foodborne illness cases each year, according to the U.S Food and Drug Administration (FDA).

Unlike their mid-20th century counterparts, however, modern food and beverage companies can’t afford the very public attention that food recalls bring. Brands that have recurring issues with food safety are unlikely to sustain the consumer trust required to last in such a competitive industry.

Eliminating food safety problems is easiest when facilities pursue a preventative approach. Developing a proactive culture and building food safety practices into processes are necessary steps in the prevention of health hazards. With these components in place, brands can achieve the level of quality assurance needed to minimize health concerns and build a stellar reputation within their market segments.

Food safety concerns

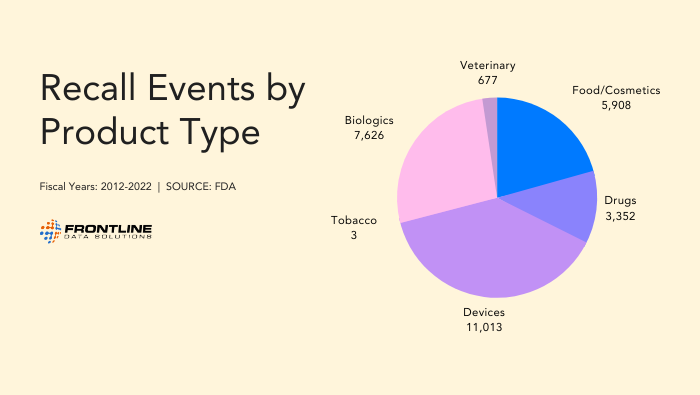

There are two main ways that food safety issues impact businesses. The first is the cost of food recalls. Between 2012 and 2022, food and cosmetic products made up 20.7% of all FDA recalls. This figure includes nearly 6,000 individual recalls, each with its own impact on the brands involved.

The incidents that spark these recalls vary in severity depending on factors like:

- Type of foodborne illness

- Number of people infected

- Location of outbreak (i.e., access to health care, size of surrounding population, etc.)

And the public health impact varies dramatically as well. There are more than 250 known foodborne illnesses, and they come with symptoms and side effects such as:

- Abdominal cramps

- Diarrhea

- Nausea

- Weight loss

- Stomach cramps

- Dehydration

- Jaundice

- Fever

- Muscle aches

This list doesn’t even cover the completely preventable hazards that come with poor food safety protocols. Metal shards, bits of plastic, and other foreign objects are more than capable of contaminating a food source. They can cause life-threatening injuries and illnesses, and a major incident may be enough to create a serious public relations nightmare.

Safety incidents like these make consumers less likely to buy food products a second time. So, avoiding issues with food safety should be an offensive brand perception strategy that all companies adopt. Luckily, there are many ways to stop foodborne illnesses and hazards from affecting consumers.

Top ways to prevent issues with food safety

Fostering a culture of prevention is extremely important in the fight against foodborne illness. Even though there are many variables to consider, you still have a great deal of control over the health and safety of your products.

Start by training your employees on the ins and outs of food safety. Then, create a workspace that encourages safe practices. With the right control measures in place, you can keep these key variables in motion to end issues with food safety for the long-haul.

Food safety training

Building a strong safety culture starts with the onboarding process. One of the easiest ways to prevent food safety problems is to teach workers best practices. Here are some topics you should consider including in your training materials:

- Top causes of food contamination at your facility

- PPE for food safety

- Signs of contamination

- Best practices for safe handling

- Statistics on the impact of foodborne illness on public health

Your food safety training should cover three principal areas:

- How to eliminate food safety hazards

- How to spot signs of contamination

- What will happen if contaminated food makes it to consumers

This ensures that your workers understand why safe handling practices are important. It also teaches them a proactive approach to food safety. Workers’ deepened understanding of food safety issues, combined with better habits, can make your products safer. And that pays dividends when it comes to building relationships with customers.

If you want to take this to the next level, consider using a learning management system (LMS) to log training. An LMS makes it easier to assign new modules and courses to your workers. And it automatically tracks their progress, so your team knows exactly which individuals and/or departments needs a refresher.

Tracking critical control measures

To eliminate issues with food safety, you have to track your approach. This is especially true if you roll out multiple changes at once.

Maybe you install a new piece of equipment or change the order of steps in the process. Without a tracking system, you won’t be able to see which of these modifications is working or not. If you audit and analyze each variable, however, you might spend less time and money on methods that don’t work.

Here are two examples of solutions you could use to track critical control measures:

Regular equipment inspections: Equipment accounts for a major source of food safety issues. By scheduling regular inspections, you can catch these problems faster. This gives your team more time to address hazards before they pose a health risk.

Action tracking software: Rather than filling out a paper checklist or form, a digital system makes it easy to log routine audits. This gives EHS teams more visibility on the assessments that they’ve done and allows for easier collaboration.

For these solutions to work, all members of the EHS team must incorporate them into their standard work. If only some workers follow the established protocols, it will be impossible to decide if your approach is effective. Therefore, don’t commit to any tracking procedure that your team is unwilling to follow. It will waste your time and likely won’t help solve food safety problems at your site.

Preventative equipment maintenance

Equipment is an often-overlooked source of food contamination. But the great news is that you can easily stop it from causing hazards with regular preventative maintenance.

You want to get away from only fixing equipment when it’s causing a problem. Instead of a reactive maintenance schedule, complete routine inspections to find potential issues.

Imagine that an area of your process involves a lot of water. The equipment in that area might be more prone to rusting. The last thing you want is for rust flakes to fall into your products. The solution in this case is to schedule a routine inspection to check for rusting (along with any other common issues).

This is just one small example of how preventative equipment maintenance can eradicate recurring issues with food safety. It feeds into a culture of hazard prevention—something that each site needs for continued success.

Food safety webinar on demand

Check out this webinar all abou the cost of poor quality performance in food safety.

Continuous process improvement

There are endless methods of continuous improvement that you can adopt. Whether you use Lean, Six Sigma, or both, the main goal is to always strive towards improving your operation.

Food safety issues often come from routine areas of the business. Broken equipment, contaminated raw goods, and more can corrupt your products before you’ve even had the chance to complete a quality inspection. Two of the easiest ways to remove food safety hazards is to vet your suppliers more closely and to build safe handling practices into your procedures and workstations.

Vendor selection

Choosing the right vendors is another key step in foodborne illness prevention. The first thing most sites look at is total cost. They want raw material suppliers who fit their target profit margin on finished goods. But what many businesses don’t do is to consider the intangible costs of working with a supplier.

When selecting vendors, you need to evaluate their food safety practices just as much as their products. Tour the facility and answer these questions:

- What kinds of behaviors do you see from the workers?

- Is the facility clean?

- Is the equipment in good condition? (Look for rust, broken/out of order signs, etc.)

- Can the vendor explain their food safety procedures in detail?

Solving issues with food safety begins at the source. If you buy materials from businesses that don’t value preventive strategies, you’ll have to work harder to ensure the safety of and quality of your own products.

Workspace configuration

Another easy way to prevent food safety hazards is to create workstations that encourage safe handling practices. You want these practices to feel effortless for your workers. Do this by:

- Organizing workstations according to the process steps

- Putting all essential tools and equipment within reach

- Having nearby storage locations for extra tools and materials

- Providing cleaning and sanitization supplies at each work area

- Making it easy for workers to access replacement PPE (hair nets, gloves, etc.)

These practices will encourage workers to always follow food safety protocols. And it will make life easier for floor managers, maintenance teams, and downstream departments. After all, sustaining safe food handling throughout the process is critical for the safety of final goods.

Other posts you might like…

No posts