There are roughly 487,000 hospitalizations and 6,200 deaths related to foodborne illness each year in the U.S. But a food safety management system (FSMS) can reduce those figures.

If your facility manufactures food products, you need an FSMS. It is vital for the protection of consumers, workers, and the environment.

What is a food safety management system?

A food safety management system is a set of practices and procedures that businesses use to ensure the safe handling of food products.

The purpose of a food safety management system is to:

- Protect workers and the public from foodborne illness

- Educate workers on safe handling practices

- Establish a systematic approach to the processing of food products

- Find and eliminate health hazards before products reach consumers

Another important benefit of an FSMS is that it helps reduce inconsistencies in the production and packaging processes. Without a standardized approach, it is difficult to trace the origin of an outbreak.

Health officials rely on organizations to carefully manage and track the flow of food products throughout a facility. If organizations do not have an FSMS, illness outbreaks may spread exponentially before officials can correct them.

You can trace modern food safety management all the way back to the 1960s with the collaboration of a major food producer and the US government. More than 60 years later, the result of this partnership is recognized and acknowledged across the globe.

Hazard analysis critical control point (HACCP)

During the 1960s, NASA and the Pillsbury Company developed a tool known as a “Hazard Analysis Critical Control Point” (HACCP). Its goal was to protect astronauts from foodborne illness by eliminating weaknesses in the production process.

Pillsbury eventually began using this tool in its own facilities due to its overall success with NASA. This led to a more comprehensive system that other brands could adopt as well. Since then, HACCP has become the standard framework for developing a food safety management system.

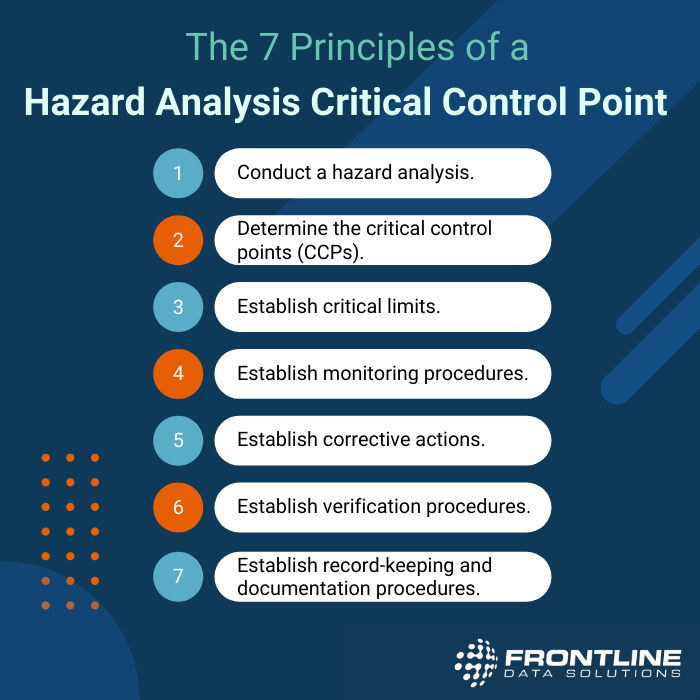

According to the FDA, HACCP has seven main principles that help facilities reduce health hazards:

Businesses can use these principles to develop a system in which they:

- Conduct regular hazard analyses

- Identify critical control points (CCPs)

- Implement control measures to ensure that the production facility effectively manages and monitors CCPs

By definition, a critical control point is any step in a process that could lead to a health or safety hazard. Because of their potential impact, these points require control measures to ensure that they don’t cause any harm.

Part of initiating an FSMS is addressing these critical control points with set protocols. Once workers are aware of the protocols, they can take a proactive role in preventing hazards and/or defects.

Creating a new food safety management system is time consuming. It requires a thorough analysis of the current process. And it also involves widespread training and reconfiguration. As such, the cost and time investment of taking these steps deters many businesses from adopting an FSMS.

Check out this video on how to implement an HACCP plan in your facility:

Costs of food safety management systems

As always, the cost of a new safety system depends on the size of your organization. For some of the largest food manufacturers in the world, food safety management systems may cost tens of millions of dollars to implement. But those businesses may have tens or hundreds of facilities with potentially thousands of workers to train.

The FDA estimates that large-scale FSMS implementation would cost the food industry $647.8 million but save $2 billion per year. Despite potential savings, the initial cost still deters many growers, producers, and packagers from setting up a system.

Benefits of an FSMS

Although the goal of a food safety management system is to eliminate foodborne illness hazards, there are many other benefits as well. An FSMS can:

- Improve brand perception

- Increase the likelihood of having return customers

- Reduce the food waste associated with recalls

- Save money related to workers’ compensation

- Protect a business from lawsuits and their associated costs

- Prevent large illness outbreaks from happening

These reasons alone should be enough to prove the value of an FSMS. Without a standard set of procedures, processes, and protocols, tracking and addressing foodborne illness outbreaks is exponentially more difficult.

If you’re not sure where to start, you can always lean on the world’s most popular framework for implementing a food safety management system.

ISO 22000

One of the most widely adopted food management systems is ISO 22000. Because this model comes from the International Organization for Standardization (IS0), many organizations across the world use it.

ISO 22000 requirements are relatively broad, allowing for flexibility among different types of businesses. In general, it outlines several requirements to ensure that an organization:

- Meets prescribed food safety regulations

- Implements and maintains a comprehensive FSMS

- Has an FSMS that follows ISO 22000 guidelines

- Communicates any food safety concerns to relevant stakeholders

- Follows its established food safety protocols

ISO 22000 certification is not mandatory, but it does provide a valuable framework for safe food handling. And it applies to businesses throughout the food chain—from farmers to distributors and anyone in between.

Improving food safety comes at a cost. But it is an investment in the longevity of your business. Unlike many other safety initiatives, programs, and resources, an FSMS impacts your workers, customers, the public, and the environment. With so much to gain on all fronts, the value of a comprehensive food safety management system is undeniable.