When it comes to workplace safety, the last thing you want is for your workers to feel that their well-being comes second to productivity. This is especially true of blue-collar jobs, where factors such as heavy machinery and repetitive movement can wreak havoc on workers’ health and safety. But what exactly does safety look like in the work environment?

If you deal with OSHA, FDA, EPA, etc. regulation, it can be even harder to balance your operational goals with external oversight. Considering your site’s safety environment in workplace policies and procedures is a long-term investment in EHS management. Below are some of the key elements to creating and sustaining a positive, safe workspace for all your workers.

Elements of a safe work environment

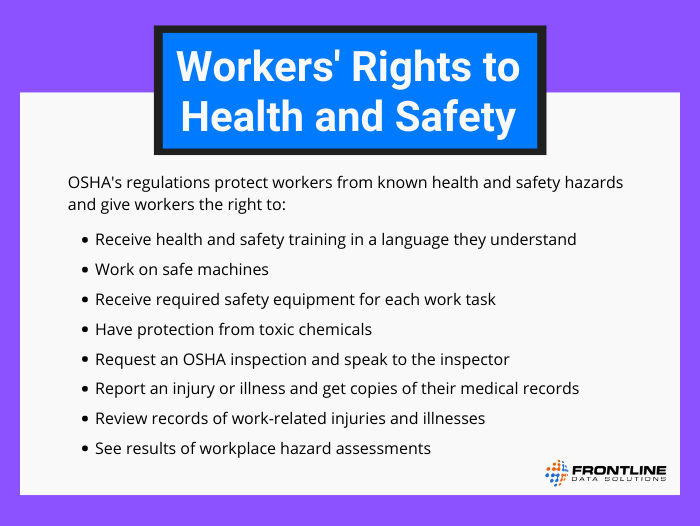

OSHA’s website features an entire page dedicated to workers’ rights and protections, which include some of the following:

Under federal law, employers must protect workers against known health and safety risks by eliminating hazards. Of course, these hazards vary from site to site. They can include things like:

- Harmful chemicals

- Fall and trip hazards

- Heavy equipment and machinery

- Ergonomic issues

It’s the responsibility of the EHS team to proactively spot and address these hazards (and more). But it’s also the responsibility of the entire leadership team to support safety initiatives and encourage workers to buy into them.

While it can be hard to change existing behaviors and systems, evaluating your site’s approach to worker safety is vital for the growth and stability of the business. Here are some of the key components to a robust safety environment in workplace practices.

Open communication

A safe work environment is one where workers are unafraid to voice concerns. And open communication needs to flow through all channels—not just managers and their direct reports.

While senior leadership may not always be able to have an “open door policy,” it’s important that they’re accessible. If your site leaders have busy schedules (as most do), set up a process for employees to reach them when they’re unavailable.

For example, you can create a sign-up sheet or portal where workers can request a meeting with leadership.

Another choice is to block off a specific day each week to walk the floor for a specific amount of time. During your walk you can:

- Answer questions

- Correct safety behaviors

- Take interest in workers’ ideas for process improvement

This level of engagement is invaluable for instilling the level of trust you need to build a safety environment in workplace procedures.

Site cleanliness

Many sites struggle to keep work areas clean and organized, but it’s essential to workers’ mental health, as well as their motivation and productivity. Some of the benefits of a clean workplace include:

- Less time spent on daily tidying and organizing

- Quicker starts at the beginning of the shift

- Fewer safety hazards

- Safer equipment and tools

- Lower likelihood of process errors

With less clutter comes a clearer focus on important work tasks. And focus is a critical part of task safety. You can create a clean, safe environment by:

- Hiring a cleaning team to do regular upkeep

- Providing workers with cleaning tools

- Initiating a strong 5S program

- Training workers on clutter-induced electrical and fire hazards

- Organizing work areas to encourage clean habits

In the hustle and bustle of the workday, employees might not always feel motivated to clean. So, if your site enforces strict productivity standards, you need to build cleanliness in the process.

If you don’t provide the tools workers need to easily adhere to 5S, you’ll struggle to maintain a safe and clean environment. And that can ultimately have a negative impact on worker engagement and retention as well.

Enforcement of safety policies

Many EHS teams work against the stereotype of “the safety guy,” whose only job is to write people up for infractions. And while this stereotype can negatively affect the safety team’s relationship with workers, it’s still very important to enforce safety policies.

One of the worst things you can do is to allow indifference to creep into your operation. The way to prevent this from happening is to be fair and consistent in how you handle safety infractions.

Ask yourself these questions:

How often do we correct unsafe behaviors?

Could our employees tell us the site’s policies on things like grooming standards or lockout tagout procedures?

Do we follow a standard procedure for each safety violation, or do we handle each situation differently?

How involved is the HR team in safety incidents and implementation of our site’s policies?

Chances are, you’ve got at least one area of policy enforcement to address. That could mean retraining workers on safety standards, rewriting HR safety policies, or getting managers to correct behaviors consistently.

Regardless of which area needs improvement, you have to remain vigilant. When these practices become static, you’ll likely allow some level of apathy to build. And over time, neglecting your site’s policy enforcement approach can lead to costly incidents.

Putting it all together

Overall, vigilance is the key to creating a safety environment in workplace policies and procedures.

You need to stay updated on worker concerns. You need to actively create a safe workspace for each employee. And you need to approach all safety infractions with the same level of consistency and fairness.

Once you have these systems in place, it’s all about upkeep and maintenance. A safe working environment relies on the same type of attention that you put into incident reports and investigations. If you implement these elements into your site policies and procedures, you can prevent incidents altogether and focus on the long-term success of your company instead.