5 why root cause analysis is a popular tool that companies use to investigate incidents, find improvement opportunities, create more efficient processes, and develop effective policies. Regardless of whether you work in operations, EHS, HR, etc., you can benefit from the 5 whys.

Free Template!

Use this 5 why analysis template to perform a root cause investigation for any incident.

What is 5 Why Analysis?

5 why analysis is a technique for finding the root cause of a problem by asking yourself “why did this happen” at least five times. Companies use this technique to investigate incidents and operational failures, efficiency issues, and all kinds of other complex problems.

Oftentimes, what looks like the root cause is just a surface issue. To understand the systems or behaviors that create an outcome, you need to consider each level of the problem. Doing the 5 why exercise helps with this by challenging you to go beyond your initial assumptions.

This technique is widely used in safety investigations, manufacturing, and quality improvement processes. In fact, OSHA highlights the importance of root cause techniques like the 5 Whys in its Root Cause Analysis During Incident Investigation fact sheet, which explains how asking the right questions can lead to meaningful corrective actions and long-term prevention.

When to Use the 5 Why Analysis

Sakichi Toyoda developed the 5 whys in the early 1900s as a tool his team could use to improve their manufacturing processes. Since then, companies have expanded the original use of 5 why analysis to many other areas of performance.

Here are some examples of situations where you could use the 5 whys to solve a problem:

- Operational failures resulting in lost time or revenue

- Safety incidents without an obvious root cause

- Quality issues (could be with an internal problem or a supplier issues)

- Recurring personnel problems like employee turnover or workplace disputes

- Production inefficiencies (individual productivity or entire processes)

The best time to use 5 why analysis is when there’s no clear cause of an issue or when the cause seems too obvious. In most cases, even if you think you know the root cause right away, there’s an underlying condition or factor that’s contributing to it.

How to Do 5 Why Analysis

There are five main steps to any 5 why root cause analysis:

- STEP 1: Define the problem clearly and comprehensively.

- STEP 2: Ask “why” at least five times to narrow down the root cause.

- STEP 3: Decide the root cause after you finish asking “why.”

- STEP 4: Find a solution to protect employees against the root cause in the future.

- STEP 5: Implement your solution and check its effectiveness over time.

The last step is crucial. If you find a root cause and do nothing about it, that’s an obvious failure. But if you do something about it and don’t check to ensure you’ve solved the problem, that’s another type of failure.

Quick assumptions perpetuate performance issues. After all, if the problem is so obvious, why haven’t you solved it by now?

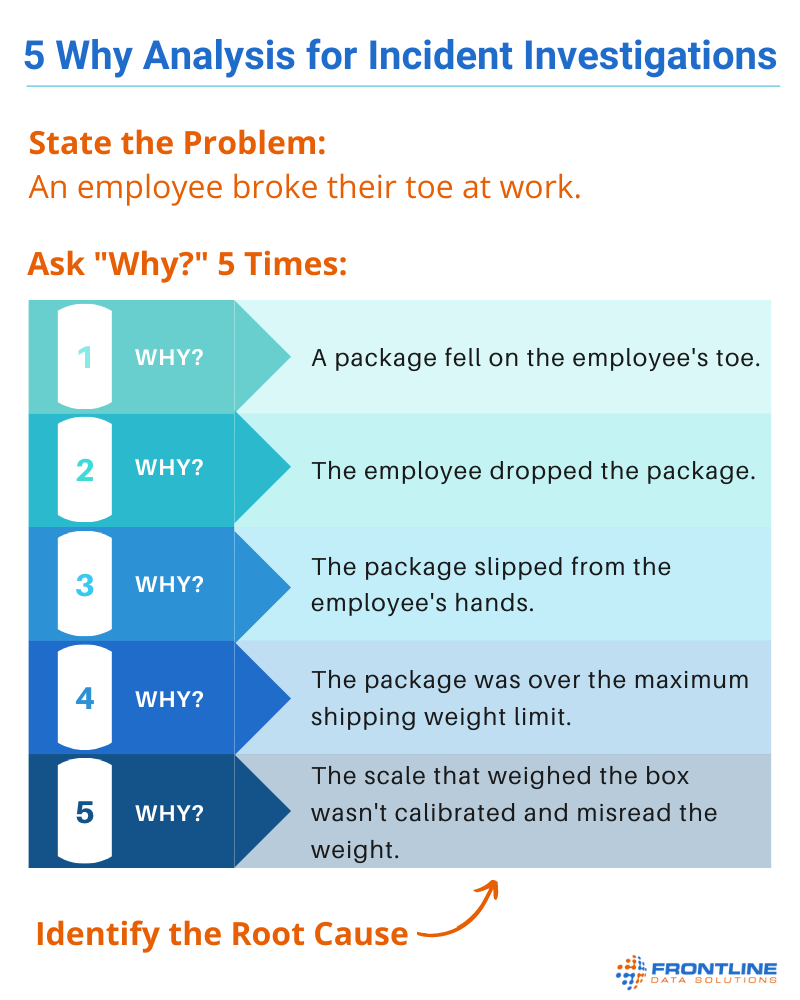

What you’ll notice when you do a 5 why analysis is that no two issues are the same. For example, you could have two separate safety incidents, in the same exact location, on the same day, with the same equipment, and still come up with different root causes.

That’s why it’s important to do separate investigations for each incident. You can only use past data to gain insight. You can’t rely on it completely to understand new problems, since there is always a different set of variables to evaluate. Consider this 5 why analysis example that you can use as a reference for your own investigations:

Avoid Blame in Your Reports

The natural instinct for most people is to look at a problem and assume that human error or behavior is the underlying cause. Here are some examples of what that looks like:

- “The employee got injured because they didn’t properly inspect the equipment.”

- “This product recall happened because an employee didn’t do a final quality check.”

- “There were 47 minutes of unplanned downtime because someone created a downstream bottleneck.”

While human behavior almost always plays a role in the outcome of an incident, it’s rarely the root cause. If your team always finds employees at fault, that’s a sign that they’re not going deep enough during their root cause analyses. Doing the 5 whys exercise allows you to better understand how the system allows workers to make decisions that affect performance.

The principles of human and organizational performance (HOP) say that “blame fixes nothing.” When an employee’s actions have a negative result on quality, safety, productivity, etc., you have to ask yourself: “What conditions allowed the employee to act in the way they did?”

Applying HOP in safety (or any area of performance for that matter) requires you to acknowledge that the system is mostly to blame. To create lasting change, you must tackle the system that fosters poor decision-making.

Documenting a 5 Why Root Cause Analysis

You can get even more out of a 5 why root cause analysis by documenting your findings. That’s because you’ll be able to go through past incidents and corrective actions to identify patterns and recurring issues. Here are the main details you should keep a record of:

- Description of the problem

- Answers to the 5 whys

- Description of your proposed solution

- List of your corrective actions and their corresponding owners and due dates

If you don’t document this information, you won’t be able to benefit from it in the future. Reviewing previous root cause investigations gives you more perspective on why certain issues happened in the past and why your control measures weren’t effective enough to prevent them again.

Using Frontline EHS to Address Root Causes

At Frontline Data Solutions, we provide a user-friendly incident management tool called Frontline ACT which is perfect for documenting your next 5 why root cause analysis. With it, you can easily assign 5 why analysis as part of your incident investigation process.

Frontline ACT for Safety Incidents

Frontline ACT is a user-friendly action tracking tool that you can use for incident management and prevention.

The system allows you to create custom forms for your team to fill out. That way, you can set up a workflow that’s specific to your processes. With Frontline ACT’s action tracking capabilities, it’s easy to see your team’s progress on incident investigations and corrective actions.