Chemical Safety Software Solutions

Safeguard your operations with chemical safety software that streamlines compliance and reduces risk.

The Safety Struggles Facing Companies in the Chemicals Sector

Chemical facilities face strict compliance requirements and significant safety risks due to the hazardous nature of their processes. For many teams, lack of standardized EHS processes makes it hard to track compliance, manage changes, and protect workers.

How Frontline EHS Software Helps

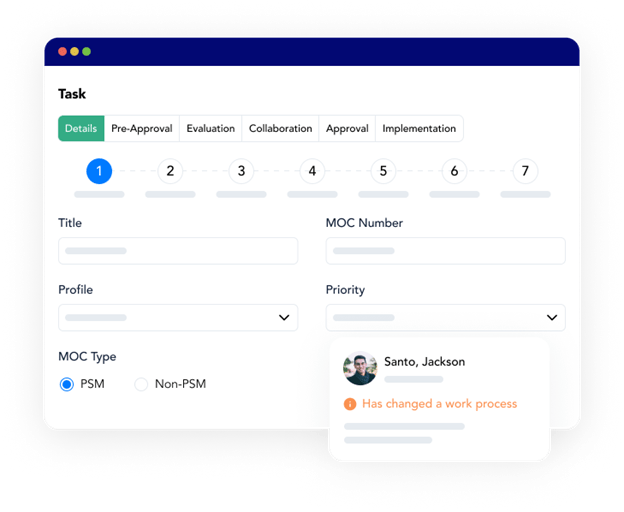

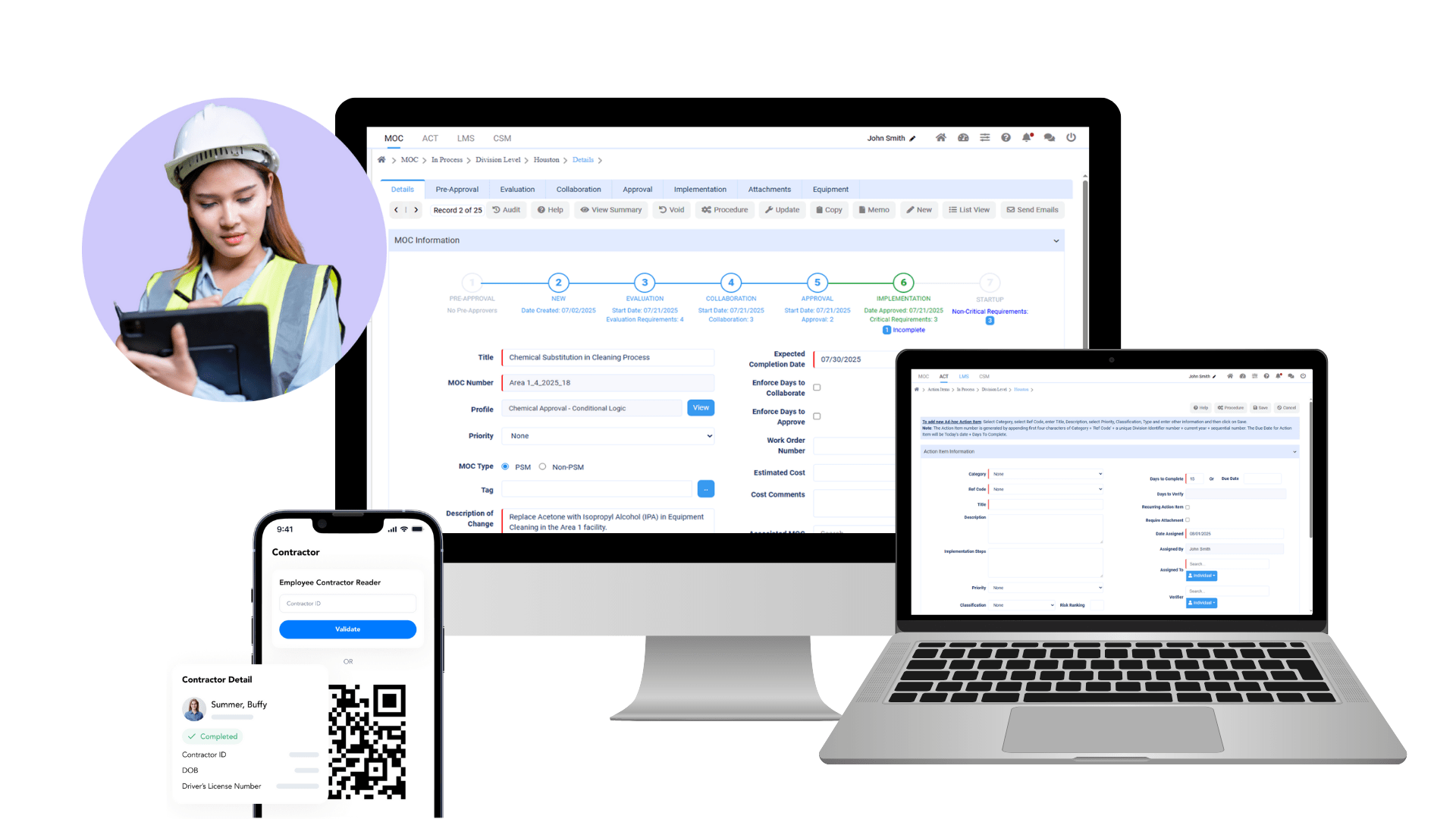

Frontline MOC

Delivers structured workflows to manage equipment and process changes, reducing risks tied to hazardous materials and reactive hazards.

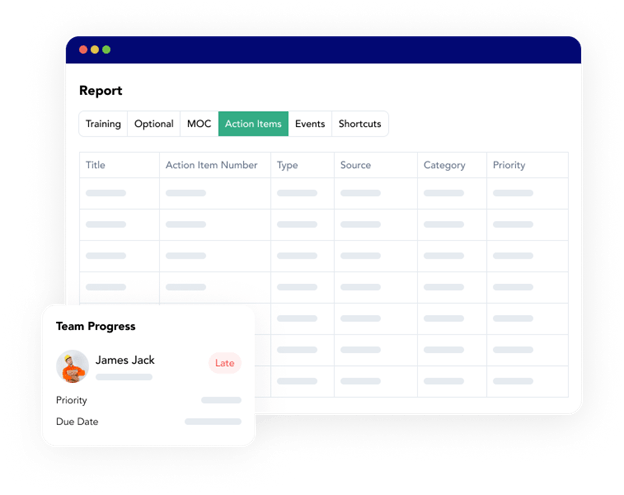

Frontline ACT

Streamlines incident reporting, corrective actions, and audits, helping chemical companies quickly identify and resolve safety issues.

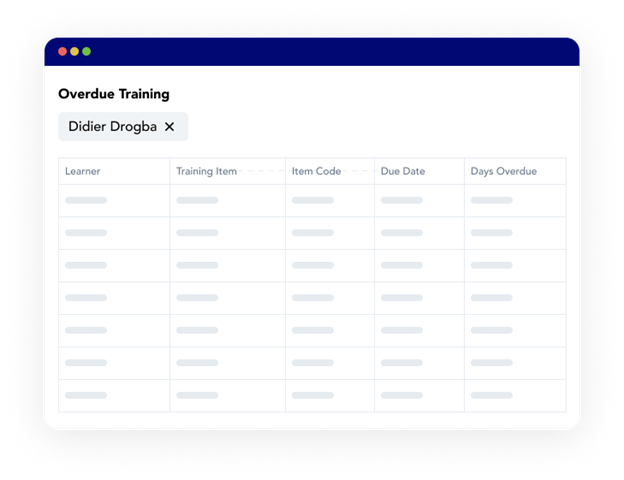

Frontline LMS

Centralizes training so employees and contractors stay qualified in chemical handling, process safety, and emergency response.

Frontline CSM

Simplifies contractor onboarding, certification verification, and work permits to maintain safe and compliant chemical facilities.

Maximize Your Investment with World-Class Support and Partnership

Partner with the team at Frontline to continuously improve your health and safety performance results.

The Safety Simplified Playbook

Simplifying your EHS program is the best way to control risks, protect workers, and run a more efficient operation. Learn what simplified safety looks like in our detailed playbook. It’ll help you find new ways to reduce your team’s workload while also improving performance.

Frequently Asked Questions

Book a Demo

Book a personalized demo with our team to learn how EHS software from Frontline Data Solutions can help you simplify safety, reduce risk, and protect frontline workers.