Routine risk assessment in workplace health and safety programs is essential for identifying and eliminating hazards. Below are the basics you’ll need to know about doing this at your facility.

Overall, risk assessment is a critical element of any effective program that encourages hazard identification and other proactive control methods.

Free template!

Use this template to establish and document your team’s approach towards risk assessment.

Hazard identification and workplace risk assessment

To identify, assess, and prioritize hazards, you should:

- Gather and review information about the hazards present or have the potential to be present in the workplace.

- Conduct initial and recurring site inspections of the workplace to identify new or persistent hazards.

- Investigate injuries, illnesses, incidents, and near misses to determine the primary hazards, causes, and safety and health program deficiencies.

- Identify trends in injuries, illnesses, and hazards reported by categorizing similar incidents and near misses.

- Consider hazards associated with emergency or non-routine situations.

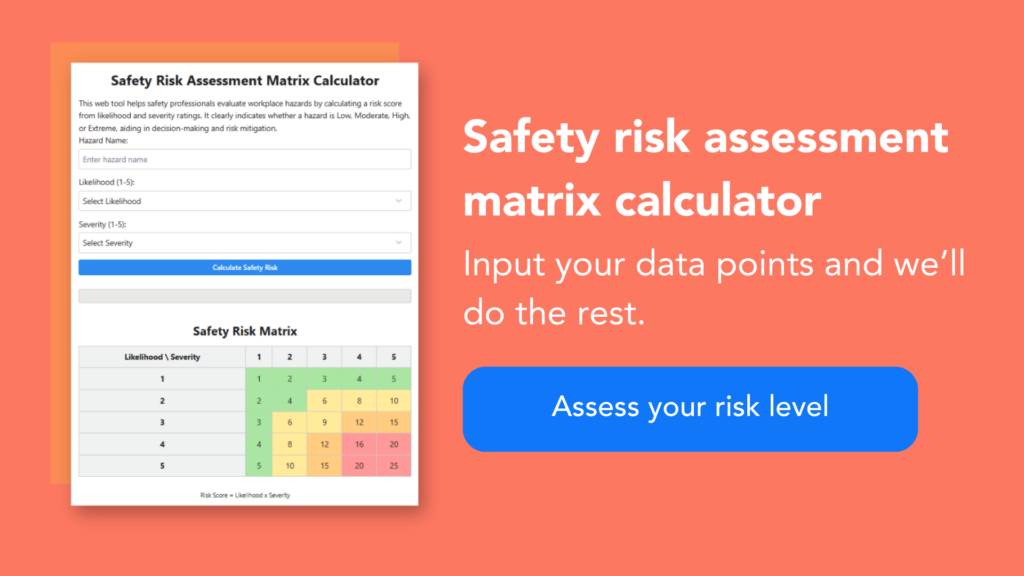

- Determine the severity and likelihood of incidents resulting from each hazard identified and prioritize corrective actions using this information.

Some hazards, such as housekeeping and slip or trip hazards, are urgent and easy to fix. For example, if an extension cord is in the walkway, why wouldn’t you remove it immediately? Correcting hazards on the spot emphasizes the importance of safety and health in the workplace and takes advantage of a safety leadership opportunity for an employee or a supervisor.

There are many actions a workplace should complete in risk assessment that could cause injury, illness, fire, explosion, environmental damage, property damage, and more. Follow the actions below for how to identify, assess, and prioritize workplace hazards.

Identify safety hazards

Hazards can be introduced over the years as processes or layouts change, equipment or tools become worn, maintenance is overlooked, or housekeeping practices deteriorate. Setting time to inspect the workplace for hazards regularly can help identify weaknesses so you can prevent incidents.

Conduct frequent inspections and have employees participate on the inspection team. Document the hazards you find and follow up on corrective actions in your risk assessment of your workplace.

Include all areas and tasks in inspections, such as storage, equipment maintenance, office functions, and the work activities of on-site contractors, subcontractors, and temporary employees. Checklists are a great tool to assist employers in checking the workplace for hazards.

Find wokplace health hazards

Identifying workers’ exposure to health hazards is usually more complicated than identifying physical safety hazards, like a chemical spill. For example, vapors may be invisible and may have no odor.

They also may not have an immediate noticeable harmful health effect. Health hazards include chemical hazards (solvents or toxic dust), physical hazards (noise or heat), biological hazards (infectious diseases), and ergonomic risk factors (repetitive motions or vibration).

Reviewing workers’ medical records can help in your risk assessment of health hazards associated with workplace exposures. Identify health hazards, conduct qualitative exposure assessments (such as using direct reading instruments), and review medical records to identify past cases of health hazards related to workplace exposures.

Conduct safety incident investigations

Workplace incidents, including injuries, illnesses, near misses, and reports of unsafe acts or conditions, provide an insight into where hazards exist. By thoroughly investigating incidents and reports, employers will identify hazards that can cause harm in the future.

The primary objective of an investigation must always be to identify the root causes to prevent future occurrences. Develop a specific procedure for conducting incident investigations and workplace risk assessment to ensure an investigation begins immediately when an incident occurs. After identifying, analyzing, and correcting root causes, communicate the investigation results to managers, supervisors, and employees to prevent a recurrence.

Emergency and non-routine situations

Employers must recognize and prepare for emergencies that present risks. Non-routine or infrequent tasks, including maintenance and startup/shutdown activities, also present possible hazards.

It’s important to develop plans for safely responding to hazards associated with foreseeable emergency scenarios and non-routine situations. When identifying emergency and non-routine situations, consider possible scenarios such as fires, chemical releases, spills, natural disasters, and workplace violence.

Implement control measures for risk assessment in workplace

The next step is to assess and comprehend the hazards and the types of incidents resulting from worker exposure to those hazards. You can use this information to develop short-term controls and prioritize hazards for permanent control in your risk assessment of your workplace for health and safety.

Start by evaluating each hazard. Consider the severity of potential consequences, the likelihood of incident or exposure, and the number of vulnerable workers. Then, use interim control measures to protect workers until you can implement more permanent solutions. Finally, prioritize the hazards so that you address those with the most significant and devastating risks first.

According to OSHA’s General Duty Clause, employers have a constant responsibility to control recognized hazards and to protect workers. After identifying hazards, you must implement adequate controls to protect workers from the risks.