It’s better to prevent incident expenses before you pay them, rather than afterwards. Adopting EHS software is one of the best ways to find improvement opportunities and implement effective preventive measures. For most companies, software provides the oversight and control they need to reduce expenses in multiple areas of performance.

Free PDF Version with Bonus Content Included!

Download the free PDF version of our EHS Buyer’s Guide to get get bonus content about the process of evaluating and selecting software vendors.

Which Incidents Generate Expenses?

Costs come from all sides of a business, and most incidents have a cost to them. Some incidents affect morale, some affect productivity or quality, and some affect the bottom line directly. It’s important to recognize which incidents pose the biggest potential impact so you can protect your company accordingly. Consider the likelihood of the following incidents at your worksite:

- Supply chain disruptions

- Product recalls

- Production stoppages or slowdowns

- Public relations or communications missteps

- Environmental contamination incidents

- Injuries, illnesses, and fatalities

- Theft or security events

You can lower the likelihood and frequency of these incidents happening by implementing effective control measures. And to do that, you need to know where areas of improvement are in the first place.

What are Some Examples of Expenses?

Tangible incident expenses come in many different forms. And some incidents result in multiple types of financial costs. A good example of this is safety incidents resulting in injuries or fatalities. Not only do these incidents involve insurance companies, but they can also flag regulatory agencies to issue citations.

Here are some examples of incident expenses you might have to deal with because of workplace incidents:

- Insurance premiums

- Legal counsel

- Regulatory citations

- Lost production time

- Revenue losses (due to PR-related issues)

- Workers’ compensation claims

- Repair costs to equipment, property, etc.

- Product scrap or rework

Any process worth implementing is worth improving. EHS software is one of the top tools you can use to reduce the likelihood of workplace incidents, thereby reducing the expenses that come with them.

How Can I Lower Incident Expenses Using EHS Software?

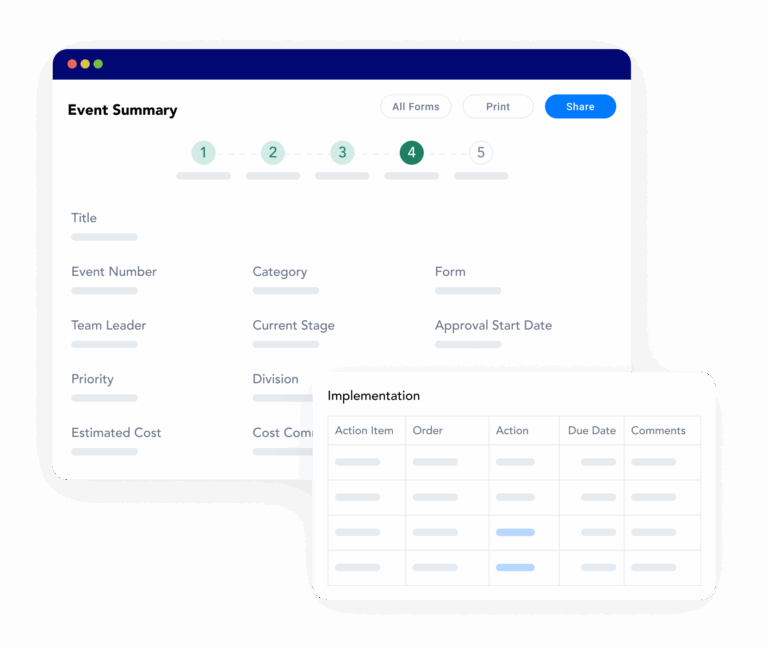

EHS software is a powerful tool for managing workplace incidents, regardless of whether they’re related to health and safety or not. You can apply EHS software tools to all sorts of incidents like product recalls, environmental contamination events, and more.

It’s all about knowing the tools within your system and understanding how to apply them to different scenarios. Let’s look at how you can reduce incident expenses with some standard EHS software tools.

Investigate and Document Near Misses

Near misses are the number one leading indicator you can use to prevent incidents and reduce expenses. Using EHS software, investigate and document every single near miss to immediately take preventive action.

Identify Incident Trends and Patterns

Tracking and documenting incidents manually doesn’t give you the same visibility as software does. Many software systems have analytics dashboards built in to help you identify trends and patterns. You can use these data points to answer questions like:

- Which processes generate the most injuries?

- On average, how many lost-time incidents do we have per month or quarter?

- Where are the biggest process training gaps in the operation?

You might also be able to quantify the costs of each incident, depending on the platform you use and what information you decide to track.

Improve Your Training Program

Many incidents and related expenses happen because of human error. For example, maybe an employee forgets an important quality check that makes an entire batch of product unusable. Or maybe someone forgets to lock out a hazardous piece of equipment and another person gets injured as a result.

With EHS software, you can make improvements to your company’s training program. By improving the quality of your course content and the training experience itself, you can boost retention. That way, workers make less mistakes and are better prepared to correct them quickly and effectively.

Set Up Recurring Reminders

With automatic reminders, you can make sure no one misses a critical deadline. This applies to projects, regulatory reports, product changes, and more. Using software should help you stay on top of your workload and make fewer oversights in the long run.

Follow Up on Workplace Incident Expenses

You need to monitor your control measures and make sure they’re effective. If you schedule follow-up tasks with your EHS software system, then they’ll become part of your standard work. This is critical for preventing repeats of the same issue.