OSHA’s process safety management (PSM) standard is designed to protect workers from hazards that come from any modifications to workplace processes. Before you can launch a new or modified system, you need to do a pre-startup safety review (PSSR).

This review encompasses everything from chemicals and equipment to workstation and personnel changes, all of which contribute to the overall safety of the system. Without this crucial step in your implementation plan, you could be putting your workers at risk for a serious incident.

What is PSSR?

A PSSR is a review that checks for potential hazards and issues with a new/modified process system or piece of equipment before it is implemented. This type of review is designed to prevent unforeseen hazards from causing a major safety incident.

PSSRs are most effective when people outside of the project team complete them. This eliminates any of the bias that might otherwise lead to a critical oversight. An effective pre-startup safety review should be structured, documented, and detailed.

With proper documentation and a comprehensive overview of the new process, system, or equipment, the auditor will be more likely to catch potential hazards.

A PSSR provides a documented review of new or modified equipment, systems, and facilities to confirm that:

- Adequate safety, operation, and maintenance procedures are in place.

- New facilities are designed and constructed with adequate engineering controls.

- Hazardous processes are appropriately controlled.

- The quality risk management process is being followed to ensure that there are no significant hazards present.

- Changes are adequately assessed for their potential impact on safety and quality.

- Any identified risks are effectively managed.

The thoroughness of this process means that safety incidents are less likely to occur. When completing a PSSR, however, you are not limited to just operational processes and equipment.

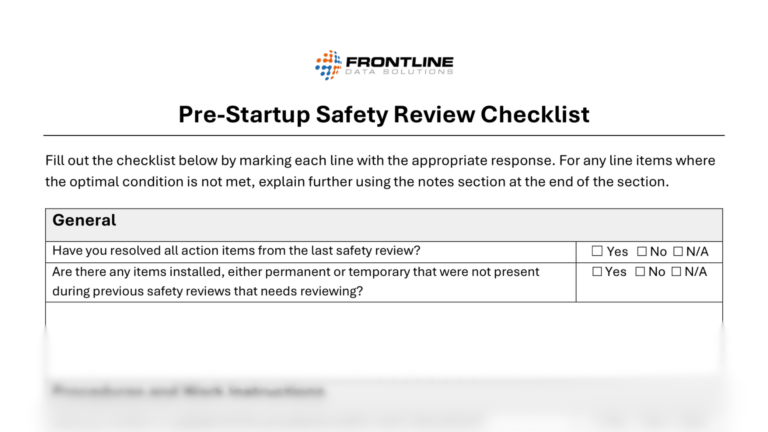

Free checklist!

Download one of our PSSR checklists to get started creating a site-specific document for your team to fill out.

What is considered a startup?

The term “startup” refers to any procedure that activates a process, piece of equipment, or system. Organizations typically perform PSSRs after an operational shutdown that has altered the facility in some way. Aside from shutdowns, startups can also be part of routine maintenance activities, such as equipment troubleshooting and repair.

There are three main types of startups to consider:

- Preventative maintenance

- Corrective maintenance

- System startups

You want preventative maintenance startups to align with scheduled downtime in your operation. This could be during routine lunch breaks, shift changes, or routine overnight closures. Corrective maintenance and system startups are trickier to plan ahead of time. Since these types of startups address components that have already caused trouble, the best you can hope for is to get them done efficiently and with minimal operational impact.

What is included in a PSSR?

The overall PSSR process is relatively simple. You must be able to view a system objectively if you want to review it for potential issues. That’s why it is recommended that someone outside of the project or operations team completes the PSSR.

A standard pre-startup safety review includes:

Document review: A check for mandatory documents like equipment user manuals, safety checklists, hazardous material handling instructions, emergency protocols, etc.

Site audit: A walkthrough of the site equipment, process, layout, systems, etc. for proper configuration and general safety

Implementation plan review: A review of the site’s plan for starting up the new/modified equipment, process, or system

In each part of the PSSR, you should note where you see deficiencies and create a system for tracking their solutions. For example, if you note that certain safety signs are missing, you need to create an action item to have them replaced. Before starting up the system, make sure that these action items are taken care of and document those results.

OSHA PSSR requirements

PSSR requirements come from three primary sources:

- OSHA – Occupational Health and Safety Administration

- EPA – Environmental Protection Agency

- HSE – Health and Safety Executive

Cal/OSHA states, in 8 CCR Section 5194.1(a)(2), that:

“A covered employer shall develop, implement and maintain a written process safety management program designed to prevent or mitigate hazards associated with hazardous chemicals used by the employer”.

EPA/Cal ARP states, in 40 CFR (Code of Federal Regulations) Part 68.110(a), states that:

“Each owner or operator subject to this subpart shall develop and implement a risk management program that is designed to prevent or minimize catastrophic releases of regulated substances.”

According to HSE Policy No. 2:

“The organization must have in place a documented, formal process safety management system to be applied throughout the organization which will ensure that process safety risks are properly identified and controlled.”

The commonality between all three regulations is that businesses must have a PSM system in place to prevent workplace hazards. PSSRs are just one important piece of this larger puzzle, but they are still important for ensuring a safe work environment.

Remember that PSSRs are helpful for multiple types of process changes. Whether you’re introducing a new chemical, upgrading your technology, or making personnel changes within the process itself, a PSSR will help you find and correct hazards before they create dangerous and potentially life-threatening situations.