Performing a root cause analysis in safety situations allows you identify and eliminate hazards. The major benefit of this is that it helps to prevent similar incidents in the future.

In my experience, it’s best to conduct your investigations within a team. Not only does this foster collaboration, but it fills in the gaps that a single individual might miss. Check out my top recommendations for identifying and addressing root causes below.

Before getting started

Before investigating, you need to address all emergency response needs and secure the scene. Once everyone’s taken care of, you can move on to the investigation step.

Incident investigations should not focus on finding fault or blame. Rather, they should instead focus on identifying and correcting root causes, as this approach demonstrates the employer’s commitment to a safe and healthy workplace.

Try to look beyond the immediate causes of an incident. It’s far too easy and often misleading to conclude that carelessness or failure to follow a procedure alone was the cause of an incident. This fails to identify the systemic changes and measures needed to prevent future incidents.

Correcting only an immediate cause may eliminate a symptom of a problem, but not the problem itself. When you find a shortcoming, ask why it exists.

Examples of questions to ask

Now that the background on root cause investigations has been covered, an example of an incident will be used to show how potential investigation questions could be created.

For example, a worker slips on a puddle of oil on the facility floor and falls, the investigation conclusion should not be limited to “oil was spilled on the floor—worker was instructed to be more careful of workplace surroundings.”

A proper root cause analyses would instead look for fundamental problems in the workplace, such as:

- Why was the oil on the floor in the first place?

- Were there changes in conditions, processes, or the environment?

- What is the source of the oil?

- What tasks were underway when the oil was spilled?

- Why did the oil remain on the floor?

- Why was it not cleaned up?

- How long had it been there?

- Was the spill reported?

Consider all “what,” “why,” and “how” questions to discover the root cause(s) of an incident. Successful root cause analyses identify all possible root causes as there are often more than one.

Properly framing and conducting a root cause investigation is vital for employers following process safety management and risk management programs.

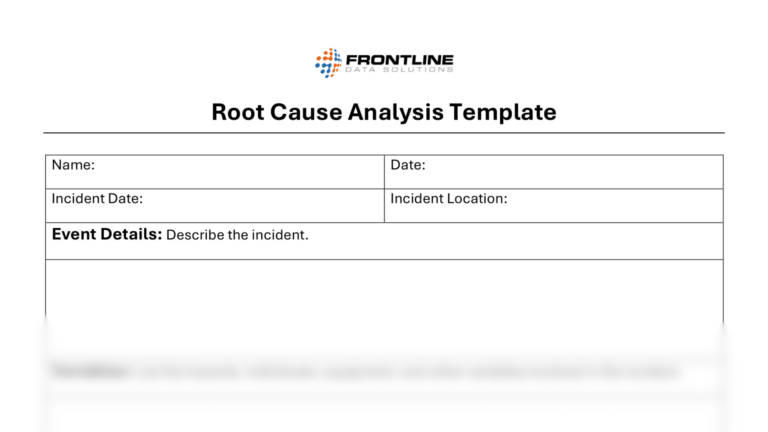

Not all incident analyses or root cause analyses will be the same. Still, there are ways to help structure and conduct investigations using a general template to make incident response time quicker.

Programs such as safety management software are a great way to keep investigations organized and up to date.

4 root cause analysis steps to follow

In my experience, here are the four main steps you should take during a root cause analysis in safety situations.

Preserve and document the scene

Preserve the incident scene by preventing evidence from being removed or altered. Document essential incident facts such as the date, location, investigator, injured employee’s name, and injury description. Documentation could also include videos or photos of the scene.

Collect information

Investigators should attempt to answer as many questions about the scene as possible by asking the injured employee and any witnesses. Some examples include:

- Who was injured?

- Who saw the incident?

- What was the worker doing?

- Which precautions or protective equipment should have been used?

- Where were other workers when the incident happened?

- What did the worker do right before the incident?

Determine root cause(s)

Finding root causes goes beyond the collection of information. It requires persistent digging into the incident, typically by asking “why” repeatedly to avoid incomplete conclusions. The more profound “why” questions asked, the more contributing factors are discovered and the closer the investigator gets to the root causes.

If a procedure or safety rule was not followed, why was the procedure or rule not followed?

Did production pressures play a role, and, if so, why were production pressures permitted to jeopardize safety?

Was the safety procedure out of date or was the training inadequate for the situation?

Take corrective action

The investigation is not complete until corrective actions have been implemented that address the root causes of the incident. Implementation should entail program-level improvements.

Addressing underlying or root causes is necessary to truly understand why an incident occurred, develop effective corrective actions, and minimize or eliminate severe consequences from similar future hazardous situations.

Using root cause analysis tools is a quick and effective way to document incidents and answer questions. Not all incidents will have the same questions, but it can help create a general template using guidelines from the steps laid out above.